This is smart manufacturing (part 3 of 3) article where I am explaining different perspective of the IIoT.

IIoT is often described as a revolution that will change life as we know it, In the areas of consumer goods, building management and others. There is some truth to this; however, across industry, IIoT will be applied more slowly as different sectors of the industrial markets evolve their specific needs and address their unique challenges.

Perspective 1: Technological elements leading the IIoT evolution

IIoT is blurring the boundaries between physical and virtual objects. This is giving way to more flexible models of accessing process and machine data – bypassing rigid automation architectures and accessing user-friendly, mobile systems based on Internet standards.

While generating and collecting data is an important aspect of IIoT, this alone will not enable manufacturers to realize the full benefit of IIoT – there are other components to consider:

- Smart connected devices that are IIoT ready will deliver an “advanced sensing system” that generates information with the first level of data analysis completed by the device itself

- An edge gateway to aggregate data, display information and connect to the cloud for advanced analytics

- Applications and services to further analyses data and put it into context to help reach business goals.

- An open and collaborative environment to allow partners to develop on a common platform

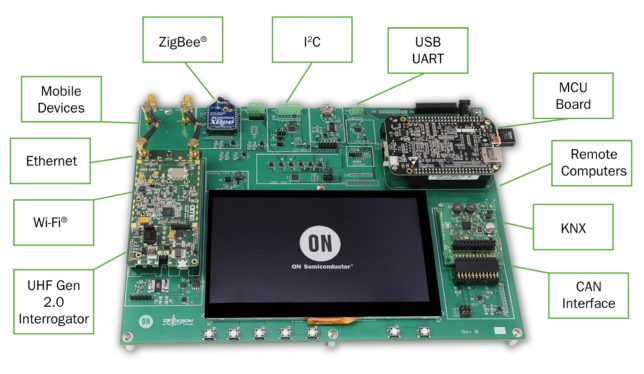

Delivering smart connected devices that are IIoT ready means embedding Internet technologies like WIFI and web services natively into those devices. Embedded digital services also become critical to support process optimization.

An edge gateway will aggregate data collected from various sources and deliver real-time business information to the right people at the right time. This is the key interface between the Internet world and the process (the things). It also facilitates value-added services independent of the control system.

A platform built on an open and collaborative environment will allow selected partners to develop specific applications that extend offerings and reach to help deliver the promise of IIoT. A consistent development environment with governance and processes will enable easy integration of IIoT platforms.

Perspective 2: Smart Machines

The smart machine concept has a number of key enablers (from the technology perspective) and drivers (from the end user and market perspective). The combination of both will lead to machines that are safe, secure, self-aware, flexible and capable of meeting demands from both end users and consumers.

The integration of internet connected devices, adoption of automated components and processes, and access to real-time production data, will empower end users to migrate to smarter machines.

Key characteristics of smart machines include the following:

- Self-awareness – Machines at the forefront of development will use sensors with embedded intelligence to distribute and automate decision making on the factory floor.

- Plug & play – Any new smart machines will need to be compatible with the existing installations or machinery from multiple OEMs. Integration into the rest of the system must be easy.

- Safety & cyber security – With security built into their fundamental designs, smart machines will improve safety of operators and minimize the security risk of increased networking.

- Connectivity – Smart machines will connect directly to the broader (IP-based) network.

- Smart machines will bridge the IT / OT gap, making available production data that can be used in numerous management settings (e.g., stock control, operator scheduling, maintenance, energy management, and product replacement).

Perspective 3: Driving business value for process control industries

Automation systems and technologies exist to drive improved value for industrial operations and businesses in a safe and environmentally responsible manner. New trends in automation should be evaluated on two levels – the technological level and the functional level.

The technological level deals with the impact of technological advancements on the technology and topology of the automation platform. The functional level deals with the incremental functionality that can be delivered on the automation platform to improve operational and business value.

The IIoT movement provides significant transformation at both levels, with the net impact being a significant increase in the value industrial companies derive from automation.

Conclusion

The good news is that technological maturity is such that businesses and enterprises can now introduce IIoT solutions by phasing in new technologies that shift their physical infrastructure base over time. The cost of connected sensors is dropping rapidly, open IP-based protocols are gaining traction at an accelerating rate and the adoption of cloud-based solutions is becoming a reality.

>>>>> <<<<<

LEAVE A COMMENT below

Your opinion and feedback are important to me